Researchers Develop AI-Driven Shape-Morphing Materials

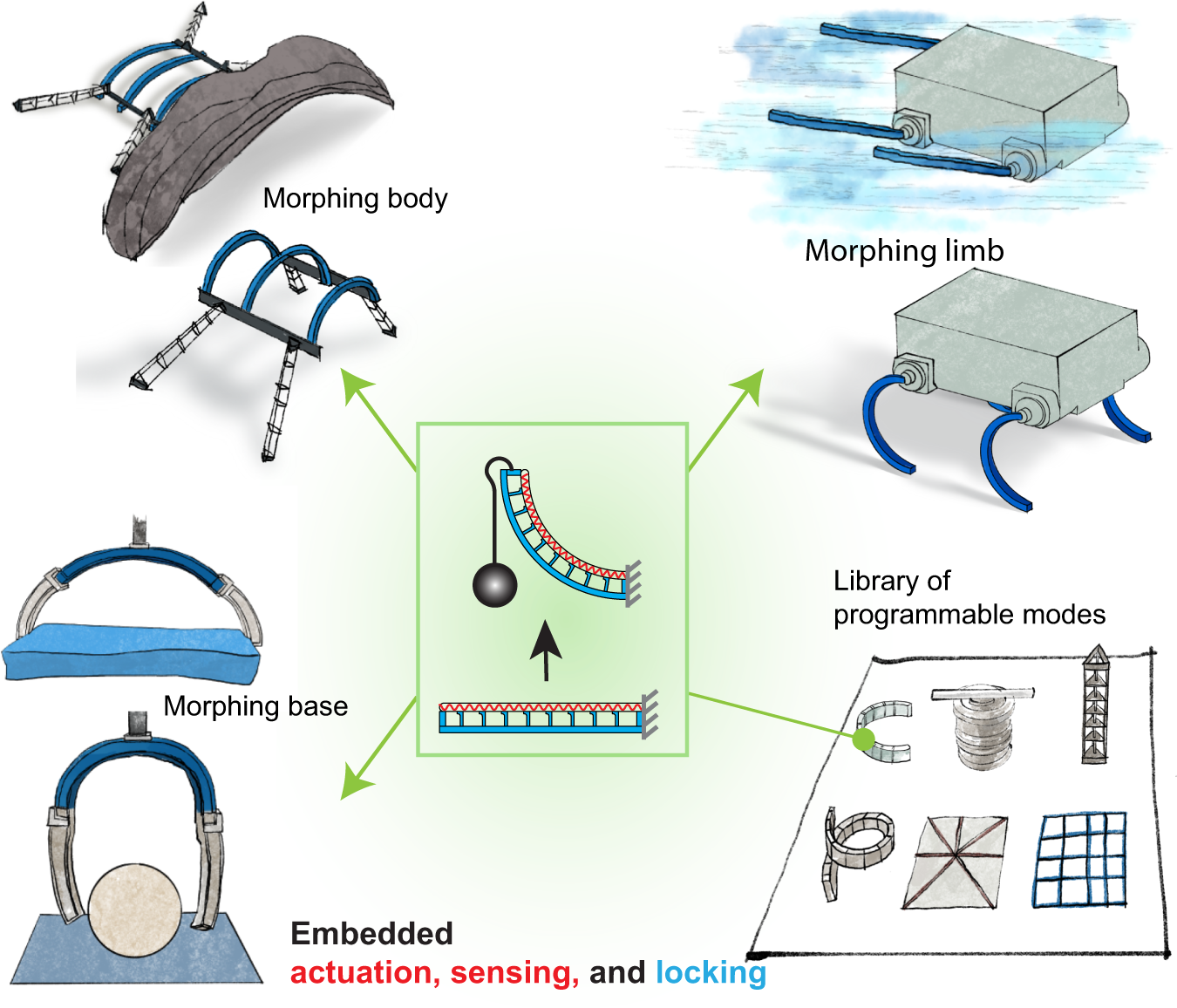

Researchers at Northwestern University have unveiled an AI-driven system that autonomously designs and fabricates shape-morphing materials, marking a major advance in programmable, adaptive engineering.

On September 12, 2025, a team led by Professors Wei Chen and Ryan Truby at Northwestern University announced a breakthrough in materials science: an artificial intelligence-powered framework that can autonomously design and fabricate materials capable of morphing their shape in response to multiple environmental stimuli. The research, published in Science Advances, represents a significant leap toward engineering materials that mimic the adaptive behaviors of living organisms, such as flowers or viruses, which can change form to suit their surroundings.

AI-Driven Design and Fabrication

The Northwestern team’s system integrates AI, physics-based modeling, and advanced 3D printing into a unified pipeline. This approach enables the rapid creation of materials that respond to triggers like heat or light, with the entire design and fabrication process completed in minutes. Unlike traditional methods, which rely on trial-and-error and are limited to single-stimulus responses, the new framework can optimize both the structure and the distribution of responsive elements, unlocking complex, multi-stimuli behaviors. According to Professor Chen, "By combining AI, physics, and digital manufacturing, we’ve created a powerful tool for developing adaptive materials that could be used in medical devices, robotics, and other technologies that need to respond to changing environments or functional needs."

Applications and Implications

The materials produced by this system often exhibit shape-changing behaviors reminiscent of biological systems, a result of the optimization process that mirrors natural evolution. Lead author Liwei Wang, now at Carnegie Mellon University, noted the synergy between AI-driven design and nature’s evolutionary strategies, suggesting that future research could deepen our understanding of programmable materials and expand their practical impact. Potential applications include artificial muscles, mechanical computers, and drug delivery devices—fields where adaptability and rapid response to environmental changes are critical.

Closing the Gap in Responsive Materials

Prior to this development, engineering multi-responsive materials was a major challenge, with most solutions limited by expert intuition and slow, iterative design cycles. The new co-design framework overcomes these barriers, generalizing to various manufacturing methods and material types. Professor Truby emphasized that this breakthrough "helps close the gap between what stimuli-responsive materials we can design and how we actually build and manufacture them for practical engineering applications."

The research is part of a broader initiative supported by the US National Science Foundation and Northwestern University’s Materials Research Science and Engineering Center, aiming to advance the discovery and design of programmable material systems. As the field of shape-morphing materials grows, experts anticipate that AI-driven approaches will set new benchmarks for adaptability, efficiency, and real-world utility.